What is reverse logistics?

Reverse logistics is one of the growing shipping trends and refers to the process of managing the flow of goods from your customer back to your business. This adds value to both your e-commerce and sustainability initiatives, as optimized reverse logistics solutions support product returns, refurbishment, recycling and more. But how does this benefit your business?

How do reverse logistics solutions benefit your business?

With up to 30% of all e-commerce products being returned by customers, it’s no wonder reverse logistics is on the rise. Once viewed as an occasional inconvenience, returns are now a vital part of the customer journey and an opportunity for your business to improve customer loyalty and retention. Additionally, it can lead to cost savings in the long run. By optimizing your inventory management and reducing the need for new product production, an efficient reverse logistics strategy stands to improve your customer satisfaction rates, minimize waste and enhance operational efficiency.

In this article, we’ll be covering the basics of how your business can start implementing reverse logistics solutions. To start, we’ll address questions like:

Key Takeaways

- How do hassle-free returns benefit your business?

- How can you successfully integrate reverse logistics into your business?

- What are some ways to provide an excellent returns experience?

- What are some return logistics challenges?

- How can you avoid refund fraud?

- How does an optimized reverse logistics system benefit your business?

- How can the right reverse logistics partner enhance your supply chain?

What are the benefits of a streamlined returns process?

Returns play a vital role in building brand loyalty. After all, a hassle-free returns process helps customers feel assured that they can easily return or exchange a product, making them more likely to purchase from your brand again. And on the flip side? As many as 57% of customers said that a negative returns experience caused them to abandon a retailer entirely. That’s why having a seamless returns process is necessary to foster repeat purchases and long-term loyalty.

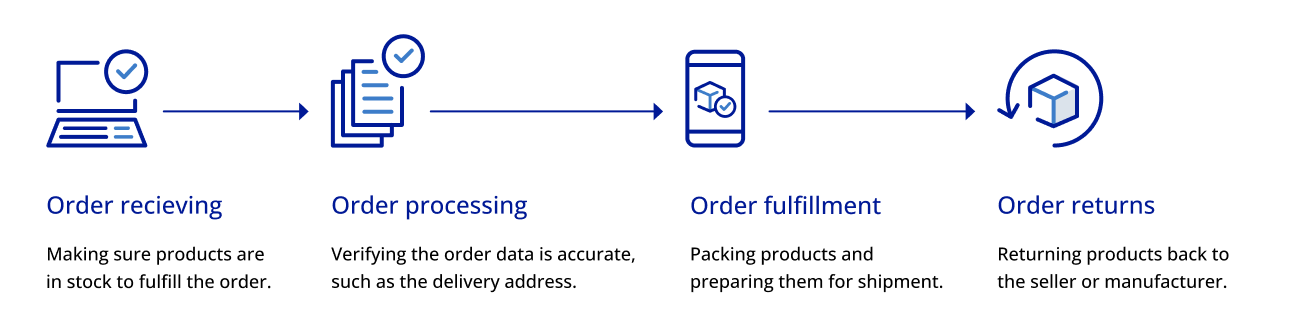

How to successfully integrate return logistics into your business

The reverse logistics process begins with your customer and ends with the product back through your business’ doors. But when it comes to integrating reverse logistics into your existing process, where do you start? Here are some key factors that any successful reverse logistics company or provider needs:

- A robust returns policy: A well-defined returns policy reduces any frustrations or obstacles your customers may have while they return products. A clear policy improves the overall customer experience, while also giving enough leeway for your business to efficiently track and handle returned items. This means your policy should spell out time limits for returns, acceptable reasons for returns and any associated fees. On top of that, it should specify available returns options for your customers—like refunds, exchanges or store credits—and be clearly visible and easy to find on your website. After all, a visible and well-defined returns policy is key for any hassle-free returns process.

- Comprehensive tracking on returns: Tracking isn’t just great for your customers, it helps your business, too. Being able to track your returns lets you accurately assess their volume and frequency, which can provide valuable insights into customer satisfaction and product quality. It also reduces the risk of incorrect refunds or lost items. Additionally, tracking returns can help you identify any potential fraudulent activities, allowing you to take appropriate measures to prevent them.

- A green solution to process goods returned by customers: Reselling, repairing or recycling returned items is crucial for reducing waste. These are all green solutions that can lower your business’ carbon footprint and promote a more sustainable and circular economy. But how exactly do you start integrating this process in your warehouses? Here’s how:

-

- When you receive a returned item, the first thing you want to start with is an inspection. If your goal is to resell the item, you need to check if it’s in good condition. If so, it can be cleaned, repackaged and resold. When items are resold, they have the opportunity to be used by someone else, extending their lifespan and reducing the need for new production. However, not all returned items are fit to be resold. This is when repairs come in.

- If any returned items are damaged, but repairable, they can be sent to a repair centre. Repairing returned items saves you the resources and energy that would’ve been required to manufacture entirely new products. It also encourages a shift towards a more sustainable mindset by putting value in the longevity of goods. Once repaired, they can be resold. And if they can’t be repaired, you’ll want to consider recycling.

- When returned items are beyond repair, recycling or donation is your answer. They can be sent to a recycling centre, where they will be properly disposed of or repurposed. It’s important for your warehouses to have efficient processes in place to handle returns in an environmentally friendly and cost-effective manner, because when you recycle returned items you’re actively diverting materials from landfills and towards new supplies and products.

- Return shipments can produce a lot of excess packaging materials, and this can turn into a lot of waste if your packages are damaged on the journey to and from the customer. That’s why you’ll want to invest in sustainable packaging. You’ll be able to cut down on waste with recyclable and biodegradable materials. On top of that, try to use the right-sized box for the right item. When each package is designed to perfectly fit an item, it also helps to reduce waste by avoiding excessive layers, unnecessary components and bulky designs. In addition, streamlining your packaging can also reduce transportation costs and emissions by minimizing the overall weight of your shipments.

- A marketing solution for brand recognition and trust: Effective supply chain management demonstrates your company’s commitment to customer satisfaction and sustainability, and you can share that success through your marketing. This lets you build trust and loyalty among your customers. Furthermore, you can analyze the data collected from your marketing efforts to determine customer preferences, feedback about product quality and potential areas where your shipping fulfilment process can be further improved. For example, if a marketing campaign that focuses on your reverse logistics solutions is successful, then you know that you’ve hit a major need that your audience is looking for and you can double-down on your returns integration efforts.

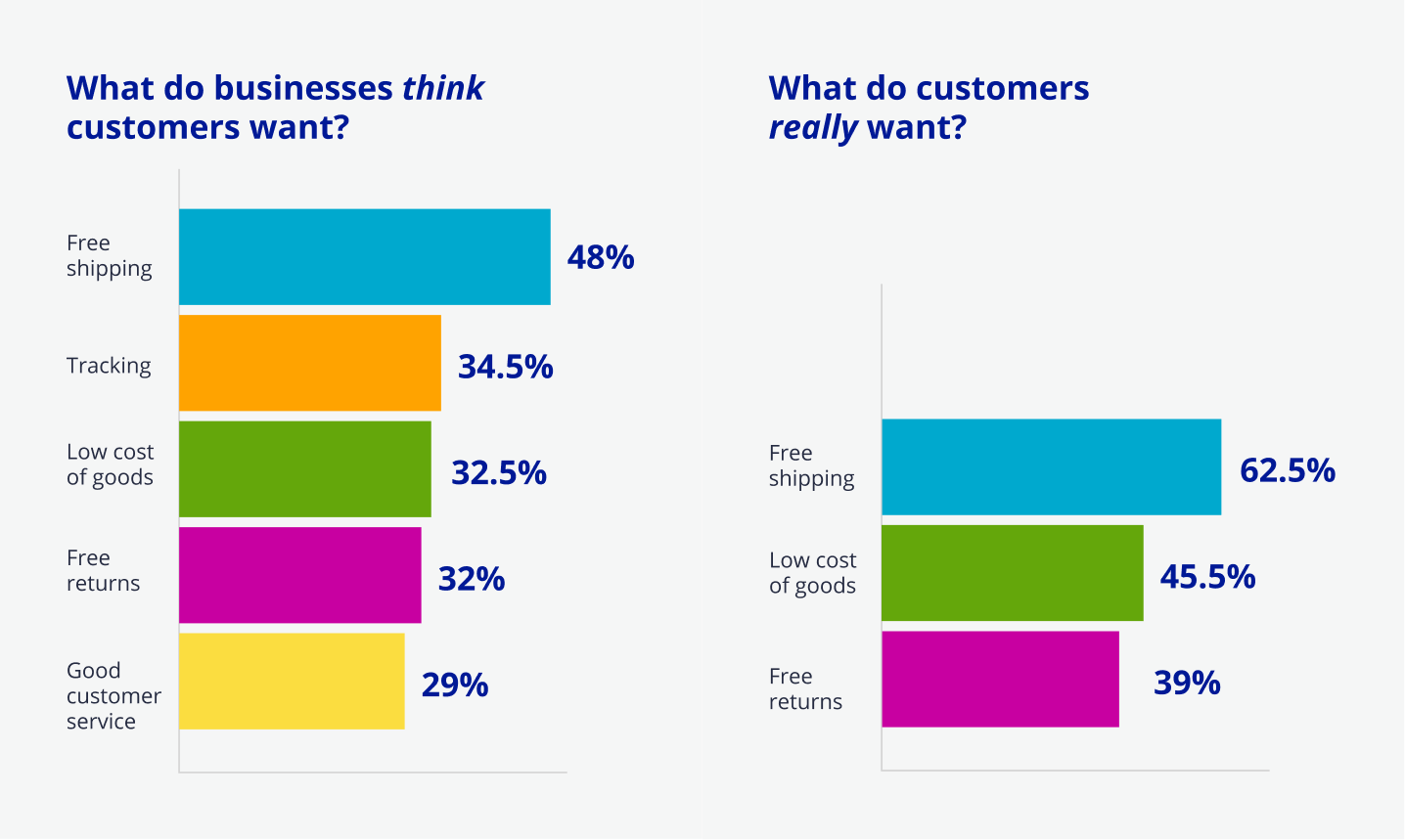

What parts of the sustainable shipping experience do your customers really care about?

When it comes to building a strong relationship with your customers and improving brand recognition, you really want to focus on the parts of your service they care about most. However, sometimes what a business expects customers to want most can be quite different from what they actually want. Learn more about how customer expectations are shaping sustainable shipping practices.

By consolidating return shipments at Purolator International’s facility, The Orthotic Group cut shipping costs and time, lowered brokerage costs, boosted customer satisfaction and significantly improved reverse logistics processes

Returns done right: Customer-centric tips for an excellent reverse logistics experience

It’s great to be aware of why reverse logistics is beneficial, but let’s dive into more detail on exactly how to run a successful returns process. Check out this list of common tips for reverse logistics companies and providers:

Understanding the challenges in return logistics

While reverse logistics can greatly benefit your business, you should also remain aware of its common challenges. By understanding what you’re likely to run into ahead of time, solving them will be an easier task. So let’s dive into these challenges and how you can tackle them.

Get expert advice on how your shipping partner can help reduce your carbon footprint.

Fraud in reverse logistics

It’s no secret that dishonest or deceptive practices can occur during the product returns process. To prevent fraud, your business can implement measures such as requiring proper documentation for all returns and implementing better verification processes. The types of fraud you’re likely to encounter include:

Benefits of optimizing your reverse logistics system

When you have your returns process all sorted out, the next step is to take it to the next level. By optimizing your existing returns process, you’ll be maxing out its efficiency and, as a result, maximizing the benefits it brings to your business. What does that look like? To start, a well-optimized reverse logistics process allows for faster and more accurate returns. This can result in a better customer experience, and more accurate insights and data to inform your business decisions. By analyzing the reasons for returns and identifying customer return patterns, you can proactively address any issues and even enhance your products based on the information you gather—ultimately improving your bottom line. This leads to further benefits such as:

- Cost reduction

- Improved customer retention

- Faster and better service

- Loss reduction

- Improved brand sentiment

- Waste reduction and greater sustainability

Optimizing your returns can be supported by the right shipping partner

Working with a shipper who is experienced with handling product returns is always ideal. However, if you’re looking to optimize your returns, you’ll want to find a shipping partner who can elevate your existing process. Look for a partner who offers:

- A sustainable returns process

- Label-free QR codes

- Convenient access points, drop boxes or store locations that customers can access from nearby

Work with a logistics company that can meet all your shipping and reverse logistics needs

While reverse logistics has undeniable benefits for your business overall, optimizing the process and making it run at its best can be a huge endeavor to tackle on your own. But it becomes a lot easier when you work with a logistics company who has returns expertise. For example, when The Orthotic Group chose to partner with Purolator to fulfil their outbound shipments and returns, they found a partner they could rely on. Purolator provided them with an all-in-one solution that improved the efficiency of their entire supply chain, including their cross-border return shipments, resulting in overall savings of 41%.

“

Now with Purolator, we’re getting the information we need to improve our logistics process each month.” – Steve Magirias, VP of Operations – The Orthotic Group

When you’re looking for a reverse logistics partner, choose a shipper who offers: