Did you know that the auto parts industry is on the rise? Car parts and accessories such as wheels, rims, brakes, hoods, engine parts and auto accessories have always been an essential piece of any automotive supply chain. But, while the sale of vehicles has been in decline, the auto parts industry is booming online, like many other e-commerce supply chain trends. The online sale of aftermarket auto parts is projected to have a high annual growth rate of 5.49% through 2030.

So, whether your customers are car and heavy truck manufacturers, car part dealers, car builders, automotive suppliers or auto shops—you need your auto parts and accessories (wheels, tires, rims, brakes and more) delivered on time as the demand for parts is high. However, given the fast-paced nature of this industry, you need to be able to stay ahead of delays or backorders, which can set back your business and result in dissatisfied customers and lost sales. In this article, we show you how to make your auto parts supply chain more predictable from the ground up. We also discuss agile solutions—like next-day automotive shipping—that can help you respond to unexpected delays or urgent demand.

Key Takeaways

- Automotive shipping 101: Supply chain basics

- What is supply chain forecasting?

- Supply chain forecasting 101: Challenges in automotive supply and demand

- Demand forecast vs. supply forecast: What’s the difference?

- How to build resiliency to counter disruption

- What are the common shipping challenges for automotive parts?

- What are the best practices for shipping auto parts locally and cross-border?

- What shipping class do auto parts fall under?

- How the USMCA has affected automotive shipping across the border

- Eight tips for making your auto parts shipments more predictable

- How Purolator can help your auto parts supply chain

Automotive shipping 101: Supply chain basics

Your supply chain is made up of the creation and delivery of your products, and its scope and complexity varies depending on its size and type. Whether you’re shipping parts for cars and trucks, or for buses and trains, what you ship is going to affect your overall logistics process. You also have to consider the purpose of your shipments, such as if you’re transporting auto parts for sale, manufacturing or vehicle maintenance. At the bottom line, your automotive supply chain should always aim to get the right parts at the right time, so you can deliver them to your customers.

While digitization has improved the tracking of materials and components, there will always be external factors that can cause disruptions in your supply chain. Preventing unexpected delays is beyond anyone’s control; however, with forecasting, you can make your supply chain more predictable. When delays inevitably occur, you’ll have the flexibility to recover faster and reduce their impact.

Common automotive supply chain KPIs

Here are a few common key performance indicators (KPIs) to keep track of, so you can measure the success of your automotive supply chain:

- Delivery accuracy: How frequently are your products being delivered to the right customers at the right time?

- Advance shipping notice: How often are your customers informed of when and where their shipment will arrive so they can prepare beforehand?

- Product handling and identification: Are your products always handled with care and clearly identified?

- Supplier collaboration and communication: Do you work closely with your suppliers to ensure your inventory is never over or understocked?

What is supply chain forecasting?

Supply chain forecasting is a way to plan and schedule shipments based on external trend analysis, your own internal data and other relevant information such as economic indicators and competitive analysis. With forecasting, you can make informed decisions about inventory management, product scheduling and supply chain optimization. Ultimately, it can help your business stay agile and prepare your inventory to meet customer demand. Some systems even allow you to identify potential weak spots in your supply chain that would benefit from closer monitoring.

To be clear, supply chain forecasting can’t predict unexpected disruptions. For example, in the last few years, many carmakers canceled their orders for microprocessors. But demand rebounded, and it was too late to call back those orders and resupply on time, forcing automakers to cut the production of new vehicles by 10.5 million units in 2021, and another 3.6 million in 2022. For other kinds of disruptions, you can use forecasting to prepare your automotive supply chain for planned, upcoming changes—like the anticipated trade agreement between Canada and India.

Supply chain forecasting: Challenges in automotive supply and demand

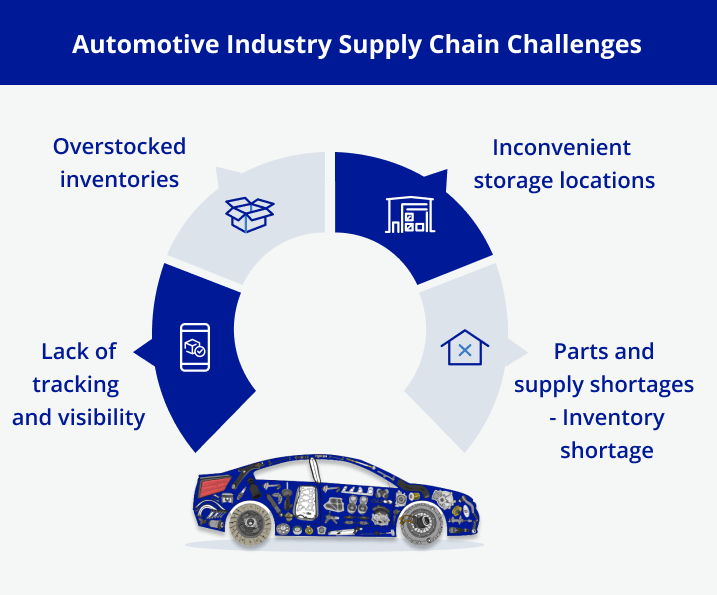

When shortages are on the horizon, it helps to pinpoint delays ahead of time. Here are some automotive supply chain issues that forecasting can help you solve:

- Lack of tracking and visibility: On average, a vehicle consists of roughly 30,000 components. That’s a lot of auto parts to track, especially when those parts are heading to different destinations. Forecasting can predict visibility issues ahead of time, making it clear that you need constant communication, part tracking at every stage, streamlined processes and predictive analytics to reduce the chances of lost parts.

- Overstocked inventories: Having efficient inventory management is crucial because there’s nothing worse than deadstock sitting on shelves and accumulating fees. By forecasting the demand for your auto parts, you’ll be able to streamline your inventory and keep your supply chain moving.

- Inconvenient storage locations: The location of your warehouse can contribute to higher inventory costs, especially if they aren’t near your end customers. This can result in longer shipping times and higher transportation costs, which can eat into your profit margins.

- Parts and supply shortages – Inventory shortage: Empty shelves are the opposite problem to overstocked shelves, but they’re both signs of the same issue: Inaccurate demand and supply forecasting. For example, the U.S. auto industry suffered an 8% drop of vehicle sales in 2022 because of computer chip shortages despite high demand for new vehicles. Mercedes-Benz mitigated these shortages by closely coordinating with direct suppliers on production planning to increase the overall predictability, transparency and robustness of their supply chain.

Demand forecast vs. supply forecast: What’s the difference?

There are two main elements of supply chain forecasting: Demand and supply. Forecasting both of these factors is crucial to getting a more accurate reading of your supply chain needs.

Demand Forecasting

Forecasting customer demand requires analyzing past sales data from distributors and retailers. This data shows the maximum demand potential from your customers while keeping your own production capabilities in mind. Key factors that affect demand include:

- Seasonality

- Trends

- The economy

- Global events

Supply Forecasting

Supply forecasting is meant to fulfil customer demand while meeting your business’s inventory production and logistics limitations. Predicting your supply involves gathering manufacturing lead times, calculating minimum order quantities, levelling production and ensuring safety stocks. Here are some key factors that affect supply:

- Inventory turnover rate

- Product lead times

- Transit times

- Warehouse receiving times

- Storage costs

How to build resiliency to counter disruption

While supply chain forecasting gives you more control when preparing for large-scale geopolitical disruptions like Brexit, for example, it can’t predict everything. What’s also important is preparing your supply chain to be resilient if a disruption happens, and giving it the flexibility to react accordingly.

- Consider multiple scenarios: Use virtual simulations of your supply chain to test multiple “what-if” scenarios and observe what parts require optimization.

- Share data for complete transparency: Work with your suppliers and share data with them regularly to make sure your decisions are based on the latest and most accurate information. This can build resiliency in the first- or mid-mile segments of your supply chain.

- Optimize your supply chain network: Streamline your network by addressing your most common automotive supply chain issues, such as determining how many facilities you should have and where they should be located.

- Improve shipment accuracy: Aim to reduce the frequency of lost or damaged shipments to improve your supply chain’s efficiency and prevent the need for reshipments.

- Invest in returns management: With a reverse logistics system in place, you’ll be adding a layer of resiliency to your supply chain. You won’t be completely dependent on your suppliers, as you’ll have the ability to reuse and recycle returned products.

- Nearshoring your supply chain: If you rely on shipments from China, Japan or Europe, consider nearshoring a larger portion of your inventory, especially the most critical parts. You could nearshore to Mexico or Latin America to accelerate the speed to market by shortening your supply chain and lead times. Furthermore, it reduces your dependence on overseas suppliers and lowers costs associated with transportation and logistics.

Nearshoring challenges and how offshoring can help

While nearshoring has its advantages, it isn’t always the right fit for every supply chain. Depending on your needs, you may find that the predictability and reliability that nearshoring offers is outweighed by these other factors. At the end of the day, nearshoring is not an all-or-nothing proposition. It’s completely possible to nearshore the parts of your supply chain that would benefit from it the most, while offshoring the rest.

What are the common shipping challenges for automotive parts?

Shipping auto parts can pose unique challenges. Depending on the size, weight and fragility of the parts you’re shipping, you’ll either need special handling services or customized packaging. We go into more detail on these challenges and their solutions below:

- Large, bulky and irregularly shaped parts: How do you ship tires and engine components, which can weigh hundreds of pounds? And what about items like car doors which don’t fit in most boxes? The answer is to work with a shipping provider who offers special handling services. This service is designed to pack and ship items that don’t fit within standard shipping conventions. This includes extremely heavy items and unevenly weighted parts (where one end is much heavier than the other). They can even help you construct custom packaging cartons and labels to contain and clearly mark your irregularly shaped parts.

- Easily scratched and fragile parts: The last thing your customers want to see is a scratched or damaged part. These kinds of parts need to be handled with special care and properly covered and padded in the carton. They tend to include mirrors, windshields and lights. It’s critical that you package them properly to avoid costly reshipments.

What are the best practices for shipping auto parts locally and cross-border?

Shipping auto parts to your customers on time is important for the health of your business, but without a clear strategy your supply chain is left vulnerable to unexpected disruptions. Don’t leave things up to chance. Instead, take the time to document a shipping plan that you share internally as well as externally with your partners. This will include things like dates for pick up and drop off, route optimization, the volume of items, the size of the truck needed, weight and size of the shipments, any special handling requirements and locations.

Automotive transportation options: Plan for both local and cross-border delivery

The start and end of your shipping journey are the fundamental basics that determine how fast it will get to your customer’s hands. Ideally, you’ll want to begin your last-mile shipment as close to the customer as possible. But it’s not always that easy. If there’s a border crossing involved to get your supplies to Canada, then getting customs documents and requirements prepared may slow down, or even halt the process. Try working with a shipping partner that offers next-day or express shipments, while also providing superb cross-border expertise to make sure your customs paperwork is accurate and filed correctly.

Schedule specialty services ahead of time

Specialty services are options that are ideal for specific types of shipments, giving your supply chain the flexibility it needs to ship oversized or fragile parts without delay. For automotive shipments, these typically include lift gate services, inside pick up and delivery and special handling services. Your shipping provider needs to know if you require speciality services ahead of time, so it’s always worth booking them in advance instead of requesting them last minute—which can lead to a delayed pick up.

Keep seasonality top of mind

Summer is the peak season for the automotive industry, particularly June, July and August. Try to plan your shipments around those months so that your auto parts arrive at car workshops or dealerships in time for customer demand. But be sure to stay clear of winter—that’s when road conditions are at their worst.

Deliver auto parts overnight

There will always come a time when you need to ship your auto parts quickly. Whether it’s because your customers urgently need parts locally or across the border, or it’s in response to a previous shipment being lost, damaged or delayed, shipping auto parts overnight is a solution you should always have available to ensure your supply chain is agile. And it is a realistic solution, as long as you’ve forecasted your supply and you work with a shipping partner who offers overnight shipping as an option. Ideally, you’ll want a provider who offers a variety of options for shipping speeds, so you can solve your next-day, urgent or two- to three-day shipping needs.

Protect your automotive parts with the right packaging

Securing your auto parts with the right packaging helps prevent damage, resulting in fewer reshipments down the line. Here are some packaging best practices to follow:

- Drain fluids from all parts that contain them to prepare them for packaging.

- Place large parts and fragile parts in tight containers and make sure they are properly cushioned with padding materials like air pillows. Minimize the air space within the container to help prevent damage.

- Package items with materials such as corrugated cartons and double-wall containers to provide an extra layer of protection.

- Separate auto parts into their own packages, crate or pallets whenever possible, especially when shipping in bulk.

- Use reinforced water-activated tape to seal your carton to stop water damage and prevent it from breaking open during its journey.

- Whenever possible, consider environmentally friendly options to help your company achieve its Environmental, Social and Governance (ESG) goals.

Label car parts to optimize the process

Here’s a tip on how to streamline the middle mile of your automotive shipping journey: picking and sorting make up the bulk of your mid-mile processing. To speed up that process, try to clearly label individual car parts. This speeds up the picking and sorting process as labourers will be able to quickly identify which part is the right one. Labelling enhancements may require IT changes that can take time and coordination, but they are well worth the effort. By improving this process, you also help ensure the right part is being sent to the correct address—meaning less delays and costly reshipments.

Discover the best practices of shipping and packing auto parts in our article.

Shipping hazardous auto parts

It’s no secret that some auto parts are considered hazardous, and require a different shipping process. These parts need to be labelled appropriately and comply with dangerous goods regulations. Work with a shipping provider who has dangerous goods specialists to guide you on the best ways to ship hazardous parts.

Examples of common hazardous auto parts and accessories include:

- Air bags

- Brake accumulators

- Car batteries and electric vehicle batteries

- Electronics that contain batteries or magnets

- Fuel and engine components

- Paint, adhesives and sealants

- Seatbelt pretensioners

- Shocks and struts

- Speakers

What shipping class do auto parts fall under?

Most automotive parts shipments are classified as freight, as long as they weigh over 150 lbs. Goods that weigh less than that are considered courier, and don’t require freight trucks to be delivered. To streamline your freight shipments, you’ll want to choose the method that’s right for your delivery:

- Less-than-truckload (LTL): A solution that saves on costs at the expense of having more stops than a truckload shipment. LTL is a way of transporting goods that do not require a full truckload. With smaller-sized LTL shipments, your shipping partner consolidates cargo from many different shippers who are moving goods in a similar direction, allowing all shippers to pay only for the portion of the LTL truckload they use.

- Truckload (TL): TL shipping means getting a single truck to carry one dedicated shipment to its destination, and you pay for exclusivity to the entire truckload. The truck will pick up at one origin point and drive straight to its final destination with minimal stops.

- Courier: A shipping solution for smaller auto parts that weigh less than 150 lbs. The speed of a courier shipment depends on whether you choose express or standard services.

- Sweep the dock: Some shipping providers let you consolidate both courier, freight and SHS, so you get all your shipments to your destinations as quickly as possible.

How the USMCA has affected automotive shipping across the border

With the finalization of the United States-Mexico-Canada Agreement (USMCA), all North American countries are now able to qualify for reduced tariffs when trading with each other. However, every industry is given a different set of trading requirements to meet in order to benefit from reduced tariffs. When it comes to shipping industrial supplies across the border, there are some cross-border regulations that are specific to the automotive sector.

- At least 75% of a vehicle’s components need to be made in Canada, the U.S. or Mexico

- Up to 45% of a vehicle’s parts must come from factories where labourers earn at least $16 USD an hour

While 75% is a harder standard to meet compared to 62.5% under the discontinued North American Free Trade Agreement (NAFTA), the USMCA does encourage more nearshore shipping with its tariff reductions. However, whether your business stands to benefit more from nearshoring or offshoring depends on what components you’re looking to ship and the solutions your shipping provider offers.

Looking for a cross-border automotive solution? Learn more in our article.

Eight tips for making your auto parts shipments more predictable

How Purolator can help your auto parts supply chain

Our automotive transport and industrial shipping solutions will help your supply chain run as smoothly as possible. Learn how we can help you save time and ship auto parts reliably as a leading provider of integrated freight, courier and logistics solutions.

✓ Experience in the automotive parts industry: Purolator has 60+ years of automotive shipping experience and has worked with many customers from well-known brands to auto parts manufacturers.

✓ A vast network and remote delivery: Our closed-loop network reaches 100% of Canadian postal codes, including remote and rural areas. We can also deliver your auto parts cross-border and to more than 210+ countries around the world.

✓ Specialty services: We offer specialty freight shipping (LTL and TL) options like inside delivery, two-person pickup/delivery and liftgate services.

✓ Special handling and dangerous goods: Our shipping staff includes dangerous goods specialists. Know that your items will travel safely and be received responsibly.

✓ Our commitment to sustainability: Impress customers by working with a shipping provider who is the first to launch all-electric vehicles. We plan on including greener buildings, alternative-fuel and electric vehicles and reducing Scope 2 emissions by 70%.

✓ Cross-border shipping solutions: We’re ready to help import and export your auto parts with customs clearance support and guidance.

✓ Next-day shipping solutions with route optimization: Need your auto parts delivered overnight? Our express service has you covered and can ship across Canada.

✓ Reverse logistics management: By sorting, repackaging or refurbishing as needed, we help streamline your ✓ reverse logistics process, avoid waste and strengthen the customer experience.

✓ Safe shipping with TAPA TSR-certified freight trucks: All our trucks have Level 1 Trucking Security Requirements (TSR) certification. We’ll deliver your shipments safely.

✓ Multiple, flexible shipping options: Choose from a variety of services from standard shipping to Mission Critical. Whether you need next-day, urgent or two- to three-day shipping, our express and ground services deliver your packages on time more often than our competitors do.

See what an expert has to say about supply chain forecasting and logistics trends.

By forecasting your logistics needs at a high level and combining it with optimizations on the ground, you’ll be able to create a more resilient and predictable supply chain. Even though forecasting can’t solve unexpected disruptions, your supply chain will be able to react to the unexpected with more agility and respond appropriately. While making these changes on your own can take a lot of time and effort, the right logistic shipping partner will guide you and offer solutions that suit the needs of both your supply and demand.